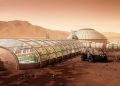

NASA’s bold venture into extraterrestrial agriculture

In pioneering work led by Dutch researchers at Wageningen University, a variety of vegetables, including tomatoes, radishes, peas, onions, spinach,...

Innovative Solutions Revolutionize Agricultural Practices: A Syngenta Perspective

The agriculture industry is experiencing a wave of innovation, with new products and technologies reshaping traditional farming practices and driving...

Harnessing Nature’s Power: Sustainable Tomato Cultivation Thrives Amid Varied Weather Conditions

Vincent de Groot Shares Insights on Weather's Impact on Tomato Production and Sustainable Cultivation Practices In the ever-changing landscape of...

Green Solutions Company: Pioneering Sustainable Agriculture Projects in Dohuk Governorate

In a significant step towards advancing sustainable agriculture in Dohuk Governorate, the installation and setup of a Multi-Span greenhouse have...

Fischer Farms: Pioneering Sustainable Agriculture for a Growing World

In the face of a rapidly growing global population and mounting challenges posed by climate change, Fischer Farms emerges as...

Shouguang’s technological leap into China’s vegetable hub

In the heart of Shouguang, a beacon of vegetable growing in China's Shandong province, a tomato revolution is taking place....