In large-scale vegetable greenhouses, can machines be used to replace labor? Can tasks such as greenhouse bed rolling, electric flat ridge rotary tilling, spraying, temperature and humidity control, and intelligent picking be taken over? Professor Teng Guifa, Dean of the School of Information Science and Technology of Hebei Agricultural University, led the research and development results of the “Agricultural Machinery and Intelligent Equipment Project of Hebei Provincial Modern Agricultural Technology Industry System Vegetable Innovation Team”. According to them, these ideas are gradually becoming reality.

On the 11th, in the multi-span plastic greenhouse of Jiahe Modern Agricultural Park, Hebei Agricultural Innovation Station, several employees were sorting the freshly picked tomatoes into baskets according to their quality and placing them in a cart. Mr. Zhou Chunjing, director of the park, said: “In addition to the transfer of vegetables between greenhouses and automatic lifting and unloading, this intelligent transport vehicle can also collect and upload data about the origin of products, classification, and weighing of vegetables in real-time.

Challenges

According to Prof. Teng China’s food production is still facing technological problems such as a low mechanization of agriculture and insufficient intelligence of agricultural machinery. The development of smart agricultural machinery is therefore urgent. In 2018, Hebei Province initiated the establishment of 18 major innovation teams for agri-product industry technology. They also gave the key support to these innovation teams’ technology research and development, in order to accelerate the cooperation of agricultural science and education.

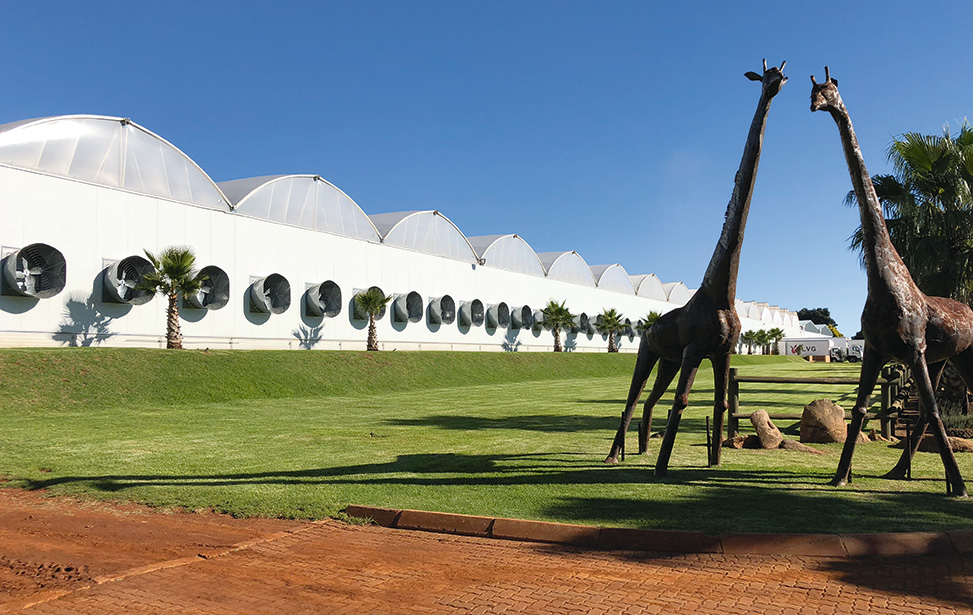

Prof. Teng said that in the past three years, his team has taken mechanization of the whole vegetable production process as main goal and actively carried out scientific and technological research. 8 types of agricultural machinery and intelligent equipment have been developed: the “electric flat ridge rotary tiller”, “laser measurement and control spinning machine”,” seedling planter”, “plant protection robot”, “greenhouse environment control equipment”, “innovative rolling machine”, and the “intelligent electric vehicle for vegetables”. These products are demonstrated in the city’s agricultural science and technology parks and test stations in Baoding, Cangzhou, and have achieved good results.

Prof. Teng said that plant protection robots, for instance, can automatically spray pesticides and nutrient solutions in the rows of a soilless greenhouse. This improves labor safety and also guarantees work safety in high temperature and high humidity environments.

New prospects

He further revealed that in the next step, the team will also carry out technical research on vegetable vine erecting robots, vegetable and fruit picking robots, amongst others, with a view to realizing agricultural machinery intelligence in all facets of the greenhouse growing process.

Mr. Liu Gang, director of the Key Laboratory of Agricultural Information Acquisition Technology of the Ministry of Agriculture and Rural Affairs, believes that this kind of intelligent equipment will soon be used on a larger scale in the industry.

Mr. Wu Huarui, deputy director of the National Agricultural Information Engineering Technology Research Center, said that the research and development of intelligent vegetable production equipment can boost the pace of mechanization and intelligentization of vegetable production in the Hebei Province.

Read the complete article at www.chinanews.com.