How about a bluehouse instead of a greenhouse? No, this is not a still from a futuristic movie, nor an art project: it is the greenhouse of Allegro Acres. To produce local peppers during colder winter months, they installed a lighting system with which they can create any combination of light wavelengths. When anything is possible, what would you do?

It was almost a year ago that the team with Allegro Acres harvested their first bell peppers from under the lights. Installing a lighting installation enabled them to grow during the winter. “The first season of winter pepper production definitely entailed a learning curve,” the team with Sollum says. Looking back at this first project phase, they highlight and discuss the key takeaways from this experience.

Earlier peak production

Some Canadian producers struggled to accommodate the unpredictable temperatures that defined the 2021 growing season. While the highest temperature in Canadian history was reached in British Columbia, heat waves were experienced just days apart from nights that were almost cold enough to cause frost in northwestern Ontario. Apple orchards in Ottawa struggled with a cold spring and dry summer, with some farmers describing yields as their worst yet. Heading into fall, pumpkin farmers across the country blamed “extreme weather” for a lackluster harvest. “With more unpredictable weather on the horizon due to climate change, the winter pepper production that was accomplished at Allegro Acres sets a necessary precedent for varying growing schedules in Canadian agriculture,” the team with Sollum says. “We saw how shifting from summer to winter production allowed the peppers to reach peak production before undesirably high temperatures were experienced.”

Crop registration

A collaboration was started with the Harrow Research and Development Center of Agriculture and Agri-Food Canada to determine the light recipe best suited to pepper production and the location of the greenhouse. Throughout the growing season, crop registration was done to monitor multiple crop parameters and optimize plant growth by adjusting their lighting accordingly. It was not just a matter of better taste, size, and appearance, but of crop yield as well.

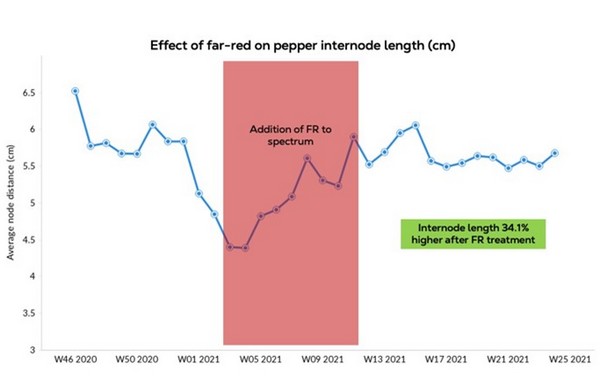

“Producing winter peppers at this scale was new territory for all of us involved in the project, so we knew that challenges would undoubtedly arise,” says Sollum agronomist Rose Séguin. “What is great about Sollum’s solution is that we could take steps to rectify an issue immediately, which makes all the difference when it comes to maximizing quality and yield.” For example, earlier in the season, undesirably short internodes were observed. The team decided to add far-red light to the spectrum to elongate stem growth. Similarly, when chlorosis affected pepper quality in one zone, the recipe was swapped with that of another zone, remedying the problem without the hassle of shuffling heavy equipment around. For those who ask: yes, the blue lights turned out as an important spectrum for the greenhouse grower.

Results of last years season

Alternating the recipes is done via Sollum’s SUN as a Service (SUNaaS) cloud platform. allowing users to drag and drop recipes in each of a greenhouse’s ‘zones’. Any combination of light wavelengths can be created. The system also makes the process of light management less complicated by dynamically calibrating LED fixture outputs based on changing ambient light. “It gives producers the freedom to implement different lighting recipes without installing new equipment – this also means that the system can be adapted as needed to account for unforeseen challenges and evolving crop plans.”

Tripled acreage

For the coming season, the winter pepper area is tripled: 12 acres of winter pepper production is being grown in Kingsville Ontario. Planting has begun a month earlier than the previous year. Different pepper varieties will be grown, and the growing environment will be adapted with new control measures such as a misting system to better manage humidity and light abatement curtains to better isolate light treatments. “It will be exciting to see how these changes interact with one another and how they affect pepper yield and quality,” the team concludes.

The partnership with the Harrow Research and Development Center of Agriculture and Agri-Food Canada will also continue. “They play a critical role in data collection and analysis which helps us provide concrete evidence to support our advocacy for sustainable, local, and year-round agriculture. They also help us analyze other metrics such as energy consumption, which we predict will be further reduced as we continue to optimize our lighting solutions to suit producers’ specific needs.”

Award-winning solution

For Sollum, it is another sign that they are only at the beginning. “We continue to grow as a business and get our game-changing LED lighting solution in the hands of more producers.” There is more good news for them: cementing itself as a major industry entrant in the world of horticultural lighting, the company has been named a winner of Deloitte’s 2021 Technology Fast 50TM Award in the Companies-to-Watch category. This award not only recognizes innovative technology but those companies that successfully translate innovation to commercial success.

“This is a highly respected designation, and receiving this award goes to show just how much progress we’ve made – in a short period of time – breaking into an extremely competitive market,” says Sollum Technologies CEO and co-founder, Louis Brun. “This is only the beginning for us as we continue to grow as a business and get our game-changing LED lighting solution in the hands of more producers.”