How many healthy tomato plants will a seed lot yield? Researchers from Agro Food Robotics at Wageningen University & Research have developed an automatic germination test that gives seed breeders and growers quick and objective answers to this question, saving cost and increasing efficiency.

Growers like to deliver uniform plants and therefore want to know the quality of the seed they order. How many plants does a batch of seed yield? Are there specimens that lag behind in growth, have a twisted stem, or a missing leaf? Both seed breeders and growers carry out germination tests.

The plants grown from these tests are assessed manually, and according to the company’s own criteria and growing methods.A seed breeder, for instance, cultivates under exactly the same conditions the whole year round, whereas in a commercial greenhouse these conditions can vary per season. “The results of germination tests can, therefore, differ from one another. This makes it difficult for seed breeders to agree on the quality of the seed and for growers to properly estimate the production of seedlings,” says Lydia Meesters, researcher at Agro Food Robotics at Wageningen University & Research.

Neural networks

In the project Exploitation of high-tech plant phenotyping tools for breeding companies and growers (2018-2021), researchers from Agro Food Robotics at Wageningen University & Research developed an automatic, standardised germination test that eliminates these problems.

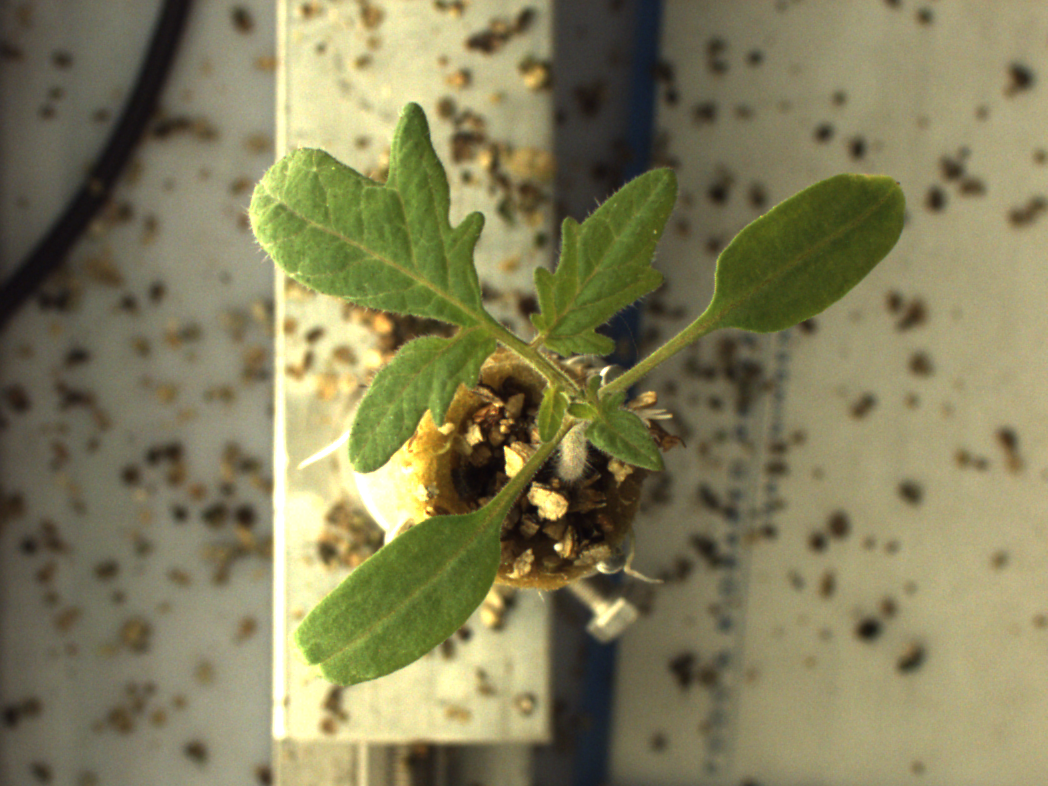

“With our MARVIN camera system, we make a large number of high-speed films of tomato seedlings and link them to classification software,” says Meesters. “The software uses neural networks (deep learning), a form of artificial intelligence that enables computers to learn based on the information they receive. In this case we make both 2-dimensional and 3-dimensional images.”

Better prediction

One of the eleven partners in the project is Paul Verbruggen, researcher at Bejo Zaden in Warmenhuizen. “We are always looking to better predict the quality and uniformity of tomato plants from our seed,” he explains.

That goal is now within reach thanks to the Wageningen research. “The Marvin camera system already appears to predict the quality of plants quite well,” says Verbruggen. “When you add new technology, such as artificial intelligence, the reliability increases significantly. The first results also indicate that it does not matter whether you collect 2-D or 3-D images of tomato plants. “For us it’s nice to know, because it confirms that Bejo Zaden are already using a good system.”

Working efficiently

Verbruggen also noted that it is difficult to reach consensus with other parties on how exactly to measure seed quality. “We are now working together on tailor-made predictive models, with which each chain partner can train its own model.” If it is up to Meesters, these models are just the beginning. “The more that modern technology is integrated into greenhouses, the more efficient companies become.”