Inagro, Vertify and Niab introduce a new substrateless hydroponic system for lamb, arugula and spinach lettuce. Four different pilot systems will be launched in the coming period. After that, organizations want to take a step towards practice.

Due to soil-related diseases and fungi, more and more field growers of leafy crops are suffering production losses. But the transition from tillage to hydroponics persists in densely planted crops, says researcher Elisa Tardy of inagro. ‘This is partly due to the fact that there are few effective systems on the market for high planting densities. With the development of a substrateless hydroponic system for these densely planted crops, we hope to remove this obstacle.

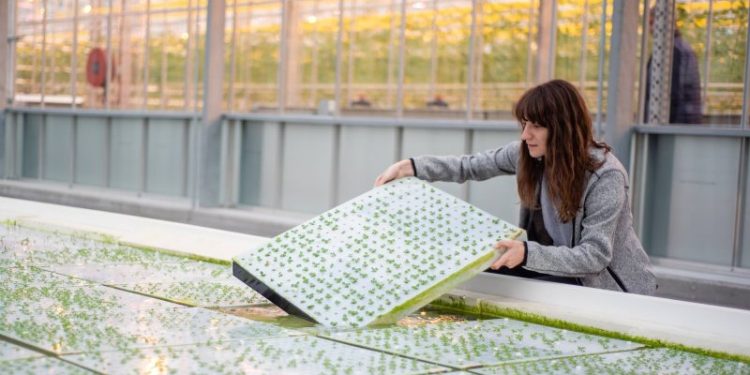

The presented hydroponic system consists of a tuned float for the deep flow technique (DfT) system. ‘It’s a reservoir of nutrient solution on which plants are grown in floats,’ points out Tardy. substrate.” Lamb lettuce, arugula and spinach are three crops that are suitable for this particular float.

Four pilot systems

The so-called Hy4Dense project has developed four pilot systems. At Inagro in Belgium, the system is located in the winter garden and consists of two different DfT pools with adapted food. “One for the germination phase and one for the growth phase,” Tardy explains. “With this system, there is no over-irrigation or mist installation.”

The presented hydroponic system consists of a tuned float for the DFT system.

The presented hydroponic system consists of a tuned float for the DFT system. © Inagro

Vertify in Zuid-Hollands Zwaagdijk has another hydroponic system option for heavily planted crops. “In this system, germination takes place in a closed grow chamber with a light and mist setup. After this phase, the plants are transferred to the greenhouse on a DfT tank,” says the inagro researcher.

According to Tardy, the above two systems are relatively expensive. “That’s why research is still being done in the UK on a system that works through cheaper plastic tunnels.” Tardy explains that two systems are being researched, one with irrigation and the other with adapted tide tables.

Implementation in practice

The drawings are already there. Now is the time to practice this step. “But before manufacturers switch to another system, it’s important to know if that system is viable,” says Tardy. “Therefore, a feasibility and social study was carried out. It showed that automation plays an important role in whether the system is profitable or not.

Because tillage for densely planted crops is already fairly automated, the hydroponic system, according to Tardy, can’t keep up. “Ideally, we automate the entire growing cycle, from seeding to harvesting and harvesting. To achieve this goal, we are looking for partners who want to work on automating hydroponic growing. Our goal is that the grower does not have to do almost any work in these processes ‘.