Koppert Cress, a global leader in cress cultivation, has carved out a significant niche in the vegetable industry by focusing on meticulous supply chain management and innovative farming techniques. Founded on an unusual accident involving radish seeds, the company has evolved under the leadership of Rob Baan, who has leveraged his extensive knowledge of the vegetable seed industry to build a successful business model.

Rob Baan’s journey with Koppert Cress began in 2002, following a serendipitous discovery of radish sprouts, which led to the establishment of the company. With a background in vegetable seeds and a passion for culinary excellence, Baan combined his expertise to create a unique market position. His approach has always emphasized the importance of a well-structured supply chain and targeted market strategies.

Strategic Supply Chain and B2B Focus

Koppert Cress has perfected its supply chain by focusing on B2B relationships, particularly with chefs. According to Rob Baan, “We meticulously control the supply chain, starting with the chefs (B2B) and creating demand back to the distributor in Toulouse and to the wholesaler in Rungis. Over time, we have perfected this chain with a year-round consistent price and created demand among chefs.” This focus on chefs rather than direct consumer sales has proven effective, as the company has been able to attend over 200 fairs annually and maintain a steady demand for its products.

Innovative Farming Practices

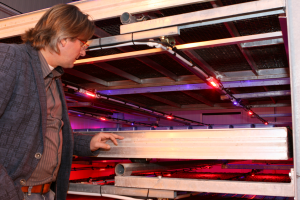

The company’s farming practices have evolved significantly over the years. Initially reliant on greenhouse cultivation, Koppert Cress expanded into multi-layer farming in 2007. This shift aimed to enhance production efficiency but faced challenges. Early multi-layer systems, while innovative, were costly and inefficient. In response, the company constructed a new greenhouse with a 5-layer rolling table system. This system, inspired by a 1960s method, improved the process but highlighted the need for further refinement.

Rob Baan notes that while vertical farming presents an appealing concept, it often proves too expensive, especially in regions with high labor costs. “Vertical farming is even more expensive in other countries. If labor costs are negligible, it might work, but using highly skilled Dutch personnel and ensuring food safety makes it very costly.” Instead, Koppert Cress has focused on improving multi-layered cooling setups to enhance efficiency.

Challenges and Opportunities

Direct consumer sales have presented challenges for Koppert Cress, as Rob Baan points out, “Consumer interest didn’t translate to sales.” The company’s B2B model, which emphasizes relationships with chefs, has been more successful. In contrast, vertical farming in urban environments faces difficulties with logistics and supply chain management, often resulting in increased traffic and operational inefficiencies. Despite significant investments in vertical farming in cities like Singapore, traditional greenhouses frequently outperform in terms of practicality and efficiency.

In summary, Koppert Cress exemplifies how a strategic approach to supply chain management and innovative farming practices can drive success in the competitive vegetable industry. By focusing on B2B relationships and continuously refining its cultivation methods, the company remains at the forefront of high-end vegetable production.