It is important to conduct water and nutrient solution analyses on a regular basis to ensure hydroponic tomatoes are receiving the proper level of nutrients.

Making sure that hydroponically-grown tomatoes receive the proper nutrient levels requires testing water and nutrient solutions. Growers also need to confirm that irrigation equipment is delivering the correct amount of fertilizer. Nutrient levels should be monitored and adjusted according to the crop developmental stage, the season, light levels and tomato type.

“In applying fertilizer to a plant grown either in soil or in a soilless medium, the goal is to match the nutrient uptake of the crop as closely as possible to the amount provided as fertilizer” (Mary Peet, USDA, Division of Plant Systems-Production, 2005). There are many reasons to do so, but a very important reason is to prevent fertilizer runoff which is actually money runoff.” For growers with open irrigation system this will hurt the most. In a closed irrigation system, excess fertilizer is recovered and recycled after water treatment.

Water sample analysis

It’s very important to regularly conduct irrigation water and nutrient solution (water + fertilizers) analyses. Irrigation water quality from a well, dam or municipal system should be determined before implementing any type of fertilization plan. Important levels growers should know include: water electrical conductivity (EC), water pH, sodium (Na), chloride (Cl) if using a municipal water source, calcium (Ca), magnesium (Mg) and sulfates (SO4). The preference is for low levels of all these elements. Water EC less than 0.5 millisiemens/centimeter (mS/cm) is a good level. If the water pH is high, a pretreatment can be done with sulfuric acid, phosphoric acid or citric acid. Optimum and safe pH levels are between 5 and 6.

Nutrient solution sampling should be conducted on a weekly or biweekly basis. Nutrient solution sampling should be taken from two sources:

1. Feed is the nutrient solution the irrigation system is pumping to the plants sampled at the dripper.

2. Drain is the leachate coming from the substrate. This is critical to a fertilization strategy.

Useful information

The information obtained from the nutrient solution analysis helps to:

1. Verify the irrigation equipment is dosing the correct amount of fertilizer.

2. Verify the EC and pH of the nutrient solution are satisfactory levels.

3. Determine the amount of fertilizer by element being absorbed by the plants.

4. Determine the amount of fertilizer that needs to be added/subtracted from the nutrient solution.

It can be determined if the amount of irrigation is appropriate by looking at the drain EC. If the EC is too high, there may not be enough water being applied to the plants. If the EC is too low (lower than the feed EC) plants may be receiving too much water.

5. Verify if the amount of irrigation is appropriate by looking at the drain EC. If the EC is too high, there may not be enough water being applied to the plants. If the EC is too low (lower than the feed EC), plants may be receiving too much water.

There are many laboratories that perform this type of water and nutrient solution analysis. It is important to choose a lab where the staff has experience in hydroponics.

Two recommended laboratories are Groen Agro Control in the Netherlands and Perry Laboratory in Watsonville, Calif.

Recommended nutrient levels

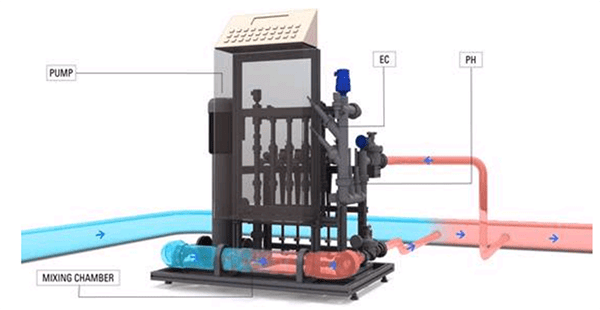

In the photo of the Netafim crop management technology fertilizer dosing unit, the blue line on the left is the irrigation water (well water or municipal water with no fertilizer). This water is pumped to the mixing chamber where fertilizers are injected and the water becomes the nutrient solution (pink line on the right). The nutrient solution flows through EC and pH sensors to make sure that the target EC and pH are maintained.

Table 1 shows the nutrient levels by element or molecule recommended for tomato nutrient solutions measured at the drain. Elemental levels at the lower or higher margins are not necessarily bad. Maintaining the proper nutrient level is crop dependent.

Table 1 reflects the desired values obtained by a drain sample analysis. By constantly analyzing the nutrient solution, the target levels can be matched that best suits the crop.

Preparing nutrient solutions

The most common chemicals for mixing nutrient solutions are mentioned in the Hort Americas article on hydroponic greenhouse pepper production.

They include:

- Ca(NO3)2 (Calcium nitrate)

- KNO3 (Potassium nitrate)

- KH2PO4 (Mono-potassium phosphate)

- MgSO4*7 H2O (Magnesium sulfate)

- H3BO3 (Boric acid)

- MnCl2*4 H2O (Manganous chloride)

- CuCl2*2 H2O (Cupric chloride)

- K2SO4 (Potassium sulfate)

- MoO3 (Molybdenum trioxide)

- ZnSO4*7 H2O (Zinc sulfate)

- Fe Sequestrene 330 (iron chelate)

General recommendations

- Some tomato varieties are more susceptible to blossom end rot (BER) http://ucanr.edu/sites/placernevadasmallfarms/files/86509.pdf) than others. Check irrigation strategy and nitrate levels since high nitrates could be the cause of BER.

- Keep daily irrigation measurements in a logbook (EC, pH and drain percentage). This is a daily task that should be performed early in the morning before the irrigation cycles start. See handheld EC/pH meters https://hortamericas.com/product-category/growing-supplies/meters/

- Compare the manual EC/pH readings with the irrigation unit readings, they should match.

- Keep K:Ca ratio close.

- Calibrate pH and EC meters once a week.

- Calibrate pH sensors on the irrigation unit at least once a month.

- Keep the irrigation system clean and flush it periodically.

- Clean fertilizer tanks every month to avoid fertilizer sedimentation.

- Keep the pH of the micronutrient stock tank low (pH 4).

For more: Hort Americas, (469) 532-2383; https://hortamericas.com.