Leading global packing equipment company, MAF RODA says the industry is now able to analyse every piece of fruit more thoroughly than ever before, thanks to huge advancements in technology available in Australia.

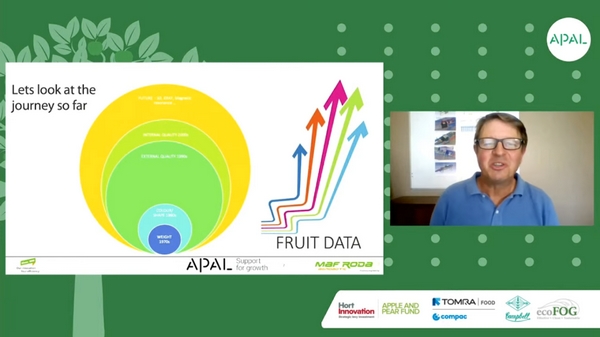

Speaking at APAL’s online Post-Harvest Seminar, MAF Oceania Sales Director, Phil Alexander says the grower, packer and equipment manufacturer are all working to achieve the same purpose in developing a “smart packhouse” into the future.

“The basis is two elements; the output of consistent high-quality product, and packing efficiency with minimal labour,” he said. “These are the objectives driving out business, which we have business in two directions. One is vision and sensor development, and the other is packing automation and robotics.”

MAF RODA is a global company, with 16 subsidiaries in 11 countries, its Victorian facility has been manufacturing since 1976. The latest offering in terms of technology, according to Mr Alexander, is the Globalscan 7.

“It has RGB and three infrared spectral images as standard,” he said. “We can also add a UV spectral image for certain applications such as citrus or mangoes. This is now achieved through a single lens in the camera – previously we would have had 4-5 cameras to achieve this result. We are now able to do it with a single lens camera. On each lane we have three cameras analysing every piece of fruit and we are able to analyse so much more in the fruit than we were 10 years ago due to the improved cameras, ever increasing computer power, better mathematics in our algorithms and growth of machine learning.”

To complement MAF RODA’s vision systems, Mr Alexander explains there are now some infrared platforms, which are used for internal monitoring.

“We have two sensors in this space; one is insight to look at dry matter and sweetness of fruit, the other is the IDD internal defect,” Mr Alexander said. “We have installed twelve of them across all different types of graders. We have been able to retrofit to whatever was previously existed in Australia, to allow everyone to have access to these internal defect measurements. It has almost become industry standard for the supply chain.”

He added that there is some interesting work going on with sensors, in particular the transfer of information from the medical sector back into fruit research. The MAF Oceania Sales Director says soft x-rays can be used to pick up contamination in fruit.

“But if we use x-ray with multiple sensors, we can develop a 3D image of fruit that can be used for picking up internal defects,” Mr Alexander said. “Likewise, magnetic resonance or MRI; there is some amazing information coming out of fruit using MRI. The downside at the moment is that it is really expensive, and it is very slow. There are a few groups in Israel that are continuing this work and trying to extend it into the real world of fruit sorting. I see this application becoming part of a biosecurity inspection process, where trays of fruit can be looked at with a portable MRI scan.”

Mr Alexander says another growth area is in data collection, because the packing shed is the only place where every piece of fruit can be inspected. Therefore, the analysis of that data can involve the orchard information, the packhouse, quality inspection and traceability.

“This can give you some really accurate information on your agronomy and post-harvest treatments,” he said. “An explosion of data can be collected throughout the whole process. Additionally, things like temperature, which is a pretty basic issue and the maintenance of a sound cool chain is pretty well known to all of us but is pretty ignored. I think that there will be some new products dedicated to recording produce history and analytics to protect shelf life. Additionally, I see that there will be software products evolve that will take all of the data that is available in the packing shed and analyse it with real statistics that give answers to growers and packers.”

In addition to the sensors and data collection, MAF has also been working with in the robotics and automation space, with several technology systems that help in the actual packing of the produce.

“The fundamental question asked to me every day is how can I reduce the packing cost to the grower,” Mr Alexander said. “This pretty much equates to the removal of labour from the process. That is increasingly important this year with the COVID-19 pandemic and the shortage of labour. Some of our progressive thinkers in the industry were probably before the 2000s, even back to the 1980s, with the adoption of pre-sizing equipment. From there we have grown to having nine pre-size MAF systems in Australia and 135 systems worldwide. Some from small growers, right up to massive 120,000 plus bin companies. Now that we have our product sorted using the pre-size, and we know what we have got and what quantities we can start looking further down the line to introducing more robotics.”

Mr Alexander says MAF RODA has two types of packing robots, the line pack and fast pack, which orientate the fruit and place them onto the trays, before they are placed into boxes.

“We have 62 of these packing robots worldwide, in various configurations,” he said. “So, we are now at the point where we can pack with very few people in the shed. Once we have it in the box there is also automation in the palletisation. But another thing that is becoming a challenge for us is using environmental packaging. MAF has been involved in the development of sustainable packaging, particularly the development of machinery for cardboard pre-pack environment. This is some of the equipment starting to come through and there is take-up of this in Australia as well.”

For more information

MAF Oceania

Phone: +61 3 5367 3155

maf@maf-oceania.com

www.maf-roda.com/en