Energy. It‘s in our nature.

Our combined heat and power engines can increase the efficiency and profi tability of your greenhouses. Because it‘s not just your plants that need to grow.

Technology, flexibility and service GE’s

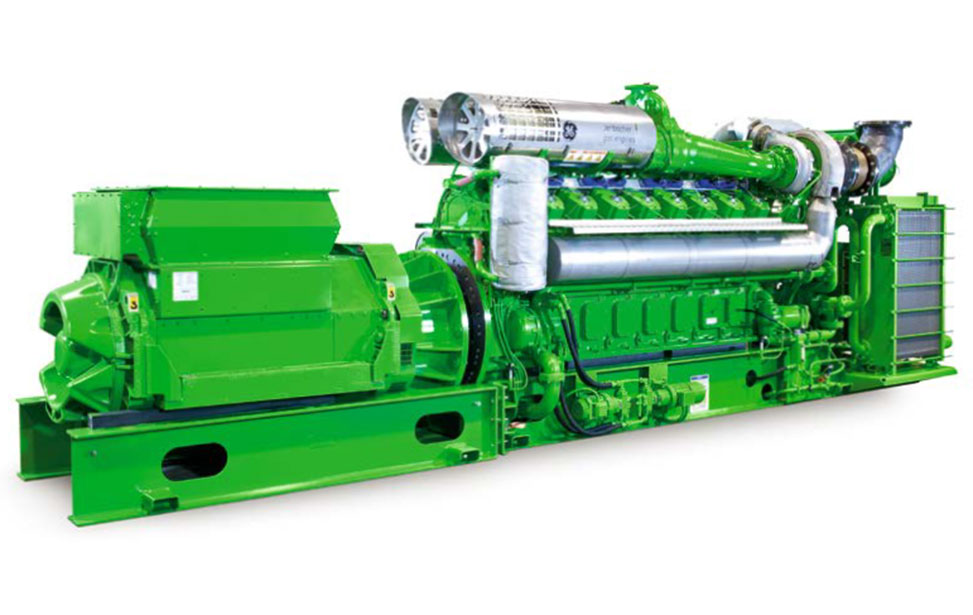

Jenbacher gas engines have a track record of more than half a century and over 14,500 installations. The main production facility, located in Jenbacher, Austria, leads the development and production of gas-fueled reciprocating engines, packaged generator sets, and cogeneration units for the efficient generation of power and heat. GE’s Jenbacher gas engines range in power from 200 kW to 9.5 MW, and run on either natural gas or a variety of other gases (e.g., biogas, landfill gas, coal mine gas, sewage gas, combustible industrial waste gases).

Faster growth with gas engines

GE’s Jenbacher combined heat and power (CHP) systems not only provide electricity for onsite or public grid use, but also heat and CO2 to fertilize plants and meet the requirements of an efficient greenhouse. By increasing the intensity of the artificial lighting that is found in some greenhouses, plants absorb even more CO2. Plant growth and the subsequent harvest yield can be significantly increased by enriching the greenhouse environment with CO2, keeping the temperature constant, and providing sufficient lighting.

The Jenbacher concept

The energy created by gas engine cogeneration systems in greenhouses can be used in various ways. The electricity can provide the power for artificial lighting and/or be fed into the public grid. And while the heat can efficiently meet the greenhouse‘s requirements, the CO2 from the engine exhaust gas can help fertilize the plants. That is because the exhaust from gas engines burning natural gas contains approximately 0.2 kg of CO2 per kWh of energy input. After the purification of the exhaust gas with special catalytic converters (SCR and oxidation catalytic converters), it is cooled down by a heat exchanger to approximately 55°C and supplied to the greenhouse for CO2 enrichment. A device that constantly measures the exhaust gas levels helps ensure the vegetation’s safety.

More information: www.ge-distributedpower.com