With the world’s population projected to reach 9.7 billion by 2050, the need for efficient, sustainable, and scalable food production systems has never been greater. Hydroponics and aquaponics — key pillars of Controlled Environment Agriculture (CEA) — offer promising solutions by allowing crops and fish to be cultivated in water-based systems, often indoors and with minimal land use. Now, thanks to rapid advances in automation and robotics, these systems are undergoing a transformation that could redefine agriculture itself.

The Power of Automation in Controlled Environments

Automation in hydroponic and aquaponic systems primarily targets three major areas: nutrient and pH management, lighting, and environmental monitoring. Automated dosing systems, for instance, use sensors to continuously monitor water quality parameters and adjust nutrient and pH levels in real-time. According to a 2024 market analysis by MarketsandMarkets, the global market for agricultural robots is projected to grow from $13.5 billion in 2023 to $25.2 billion by 2028, driven by increasing adoption of automation in CEA and precision farming.

Similarly, smart lighting solutions, such as LED systems optimized for plant growth, allow farmers to control photoperiod and light intensity with precision, improving both energy efficiency and crop yields. These lights, often integrated with sensors and IoT platforms, adjust based on crop type, growth stage, and environmental feedback.

Meanwhile, IoT-enabled climate control systems automatically regulate humidity, temperature, and CO₂ levels — crucial factors in closed-loop systems. The use of data analytics and AI allows farmers to predict and prevent system failures, schedule maintenance, and optimize production cycles.

Case Studies and Practical Results

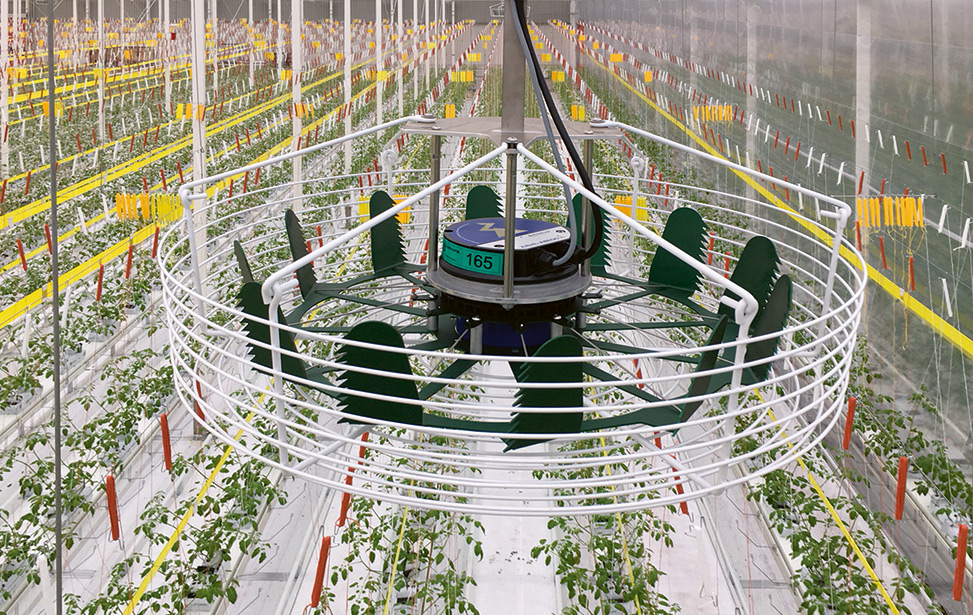

A notable case is Iron Ox, a U.S.-based startup using fully autonomous robots to manage hydroponic farms. Their robotic arms and mobile carts handle planting, harvesting, and monitoring, allowing for minimal human intervention. Their facilities have demonstrated up to 90% water savings compared to traditional farming and substantial labor cost reductions.

In the Netherlands, GrowX has integrated AI and vertical hydroponics with robotic seeding and harvesting systems. This has led to 30% increases in yield per square meter, along with near-complete automation of the growing cycle.

Meanwhile, research from the University of Arizona’s CEAC (Controlled Environment Agriculture Center) reports that automated aquaponics systems with real-time monitoring can increase yield by up to 40% compared to manual systems, while cutting energy and water usage.

Overcoming Challenges with Emerging Technologies

Despite these gains, barriers such as high initial investment, energy consumption, and technical complexity remain. The setup cost for a fully automated CEA system can exceed $500,000 per acre, limiting access for small and mid-size farms.

However, emerging technologies offer promising solutions. AI-powered platforms like Motorleaf are reducing the need for extensive labor and training by offering predictive analytics that improve decision-making in real time. Off-grid power solutions — including solar panels and battery storage — are becoming more efficient, making energy-intensive systems more sustainable and accessible in rural or remote areas.

Automation and robotics are not just futuristic concepts — they are already reshaping the way we grow food. By enhancing the productivity, efficiency, and resilience of hydroponic and aquaponic systems, these technologies are helping to address some of the most pressing global challenges: food insecurity, resource scarcity, and climate change. While hurdles remain, continued innovation and investment in energy-efficient and scalable solutions are key to unlocking the full potential of controlled environment agriculture. For farmers, agronomists, and agricultural engineers, the message is clear: the smart farm is no longer a distant vision — it’s the future of farming, and it’s already here.